Passivation For Zinc Alloyed Steels

- BT

- China

Passivation For Galvanized Steel is Chromium-free surface preparation product preparation to functional coating , so can reduce the enviromental footprint for steel mills.

the passivation, applied to galvanized sheet can add excellent corrosion protection for during storage and transport.

the passivation can reach to the requirments of customers, eg. Moisture and heat resistance ,Corrosion resistance, heat resistance and so on.

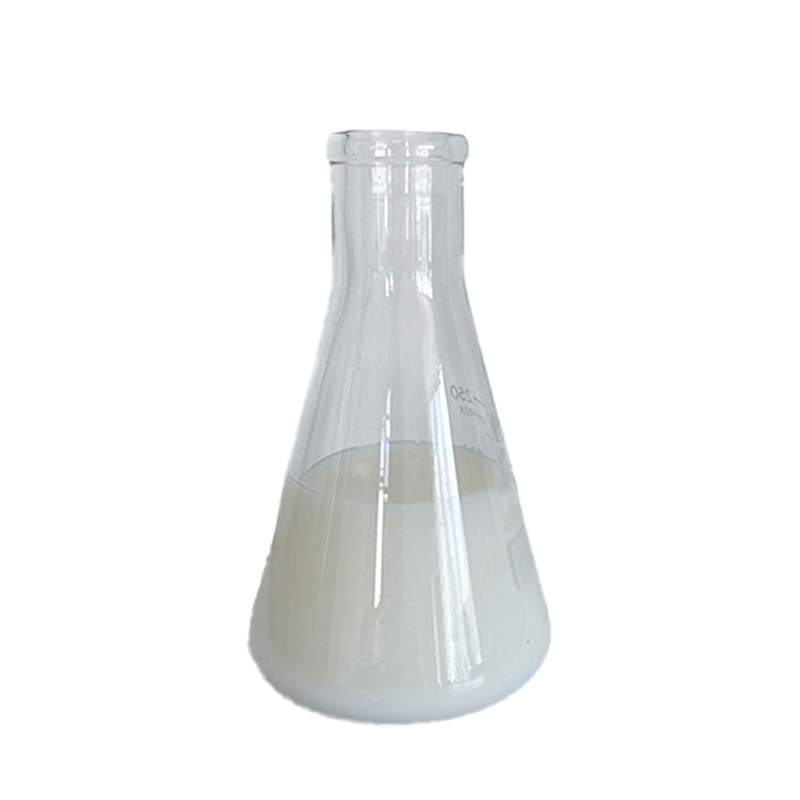

bt-2363 does not contain Cr6+ environmental protection trivalent chromium passivation liquid, by less content of trivalent chromium salt, organic silicone resin, accelerator, crosslinking agent and special additives refined. It is suitable for the passivation treatment of the surface of the plate by GI, GA and GL. Although the content of trivalent chromium in 2363 is small, it has excellent corrosion and temperature resistance of the metal and improves the adhesion of the passivation film. Silica is added to the passivation liquid to form a colloidal solution, coated on the galvanized sheet and dried, will make the passivation liquid solidified into a gel, and the galvanized sheet has a strong adhesion, for the strip in the storage or transportation process can prevent metal rust and prevent metal discoloration.

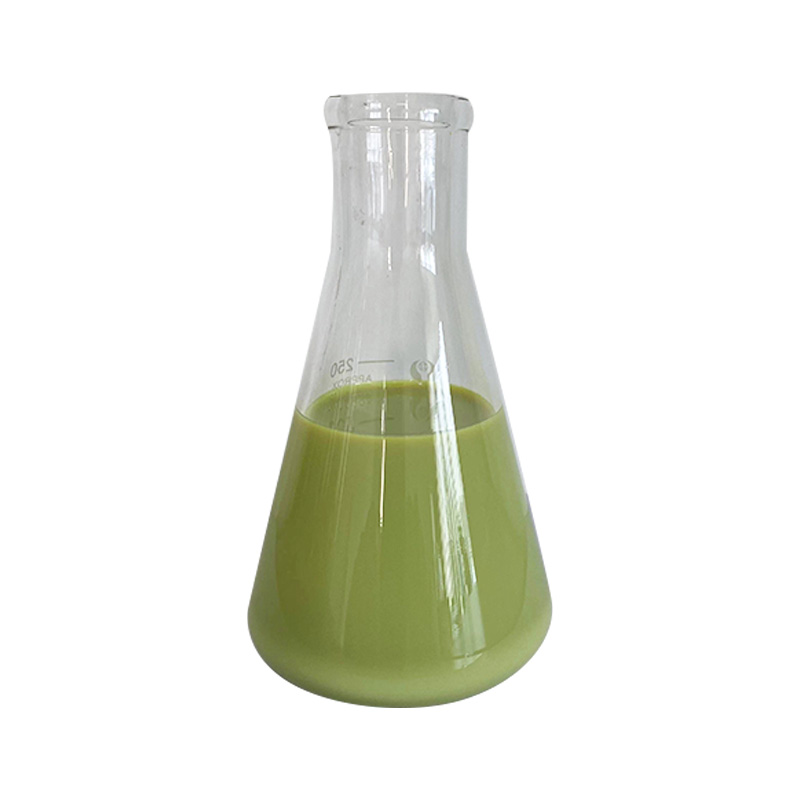

bt-2359 is our company's science and technology personnel developed to replace the latest environmental protection products containing chromium passivation liquid, mainly composed of organic resins, silanes, corrosion inhibitors and additives, in line with the environmental protection requirements of RoHS China. Consistent with the performance of bt-2363

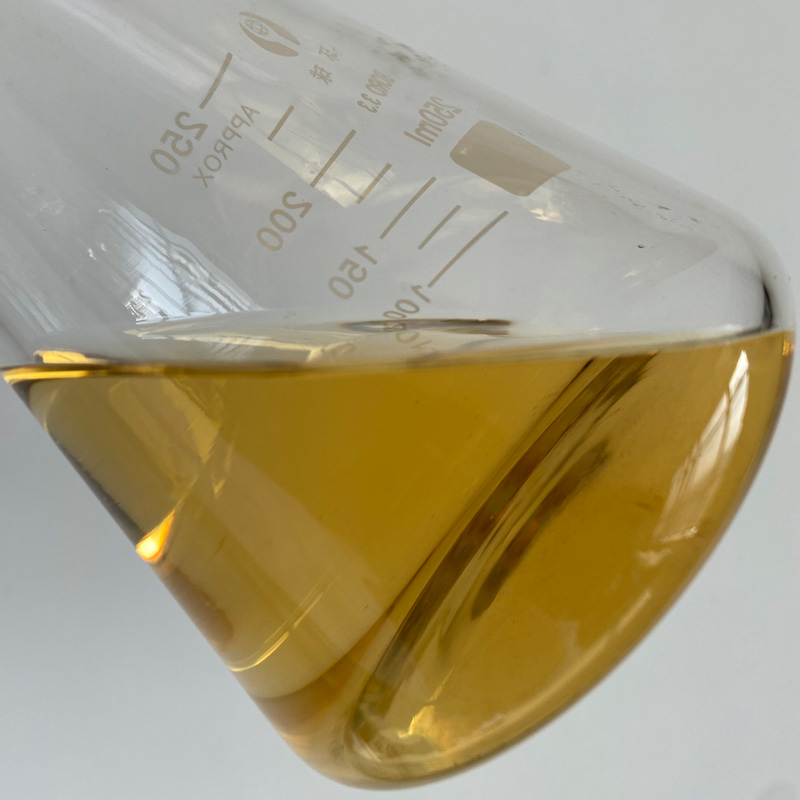

Bt-2360 is the latest environmental protection product developed by our company's scientific research personnel to replace anti-fingerprint solution containing chromium, mainly composed of organic resins, silanes, corrosion inhibitors and additives. Comply with RoHS China environmental protection requirements. Compared with the other two products, the 2360's film can better prevent fingerprints from getting on, making the metal surface look cleaner and brighter

Bt-2360 and bt-2359 is chromium-free passivation liquid but compared to bt-2363 trivalent chromium passivation liquid can be used in a kind of plate, EG plate surface passivation treatment, which shows that the future development of the world passivation liquid will be close to chromium-free passivation liquid, our company set great efforts to develop chromium-free passivation liquid, focusing on the future, The company will always follow up the international requirements for passivation liquid, always follow the international trend

A solution that dulls the surface of a metal. Generally used for zinc plating, cadmium plating and other plating after processing. The purpose is to form a surface state on the surface of the coating that can prevent the normal reaction of the metal, improve its corrosion resistance, and increase the appearance of the product. Compared with hexavalent chromium passivation liquid phase, there is no bright color film, the appearance of metal before passivation is no difference, more bright and beautiful

Chromium occurs in nature as a divalent to hexavalent oxidation state. However, only trivalent and hexavalent chromium are stable enough to be practically used in electroplating production. Traditional passivation solution is usually composed of hexavalent chromium compound and trivalent chromium compound as the main raw materials. Due to the simple operation, low cost and easy control of hexavalent chromium passivation liquid, the passivation film formed is bright color, outstanding weather resistance and wear resistance, and has self-repair function, so it is widely used. But at the same time, hexavalent chromium compounds are highly toxic and carcinogenic. In recent years, the use of hexavalent chromium, a highly toxic carcinogen, has been strictly restricted in environmental regulations all over the world and will eventually be banned. Driven by environmental protection, clean production and higher corrosion resistance requirements of steel parts in the automobile industry, great progress has been made in the research and development of trivalent chromium passivation and chromium-free passivation. The formula and process of trivalent chromium passivation are becoming more and more perfect. However, our company still wants to contribute to the environmental protection of China and the world by producing more chromium-free passivation solution. As far as possible to reduce the chromium ions in the trivalent chromium passivation solution, and let the trivalent chromium passivation solution can still maintain the original effect, in order to protect the environment