Passivation For Galvanized Steel

- BT

- CHINA

Passivation For Galvanized Steel is Chromium-free surface preparation product preparation to functional coating , so can reduce the enviromental footprint for steel mills.

the passivation,applied to galvanized sheet can add excellent corrosion protection for during storage and transport.

the passivation can reach to the requirments of customers, eg. Moisture and heat resistance ,Corrosion resistance,Heat resistance and so on.

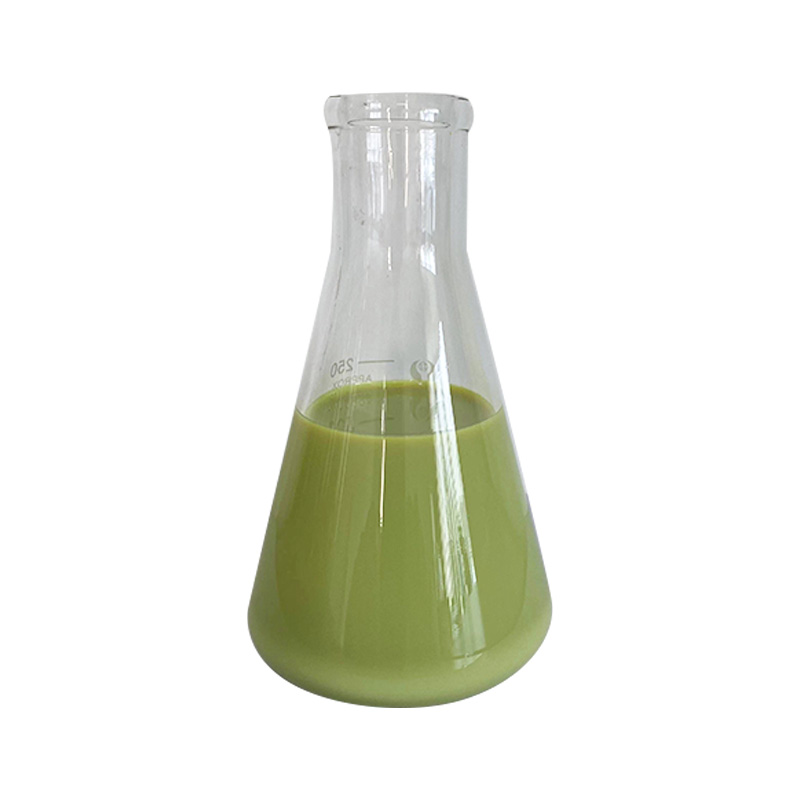

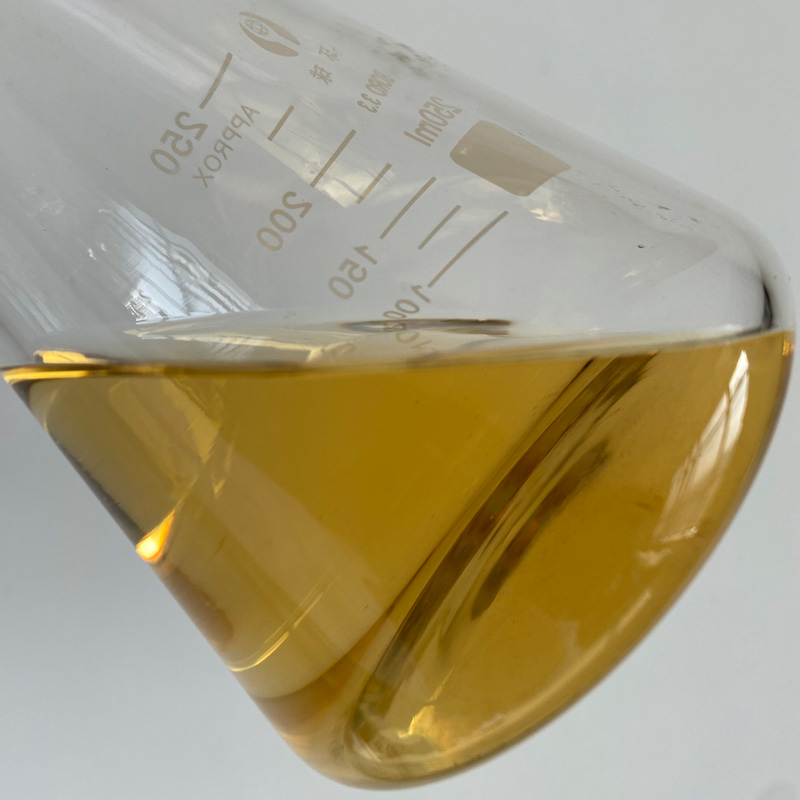

BT-2363 does not contain Cr6+ environmental protection trivalent chromium passivation liquid, by less content of trivalent chromium salt, silicone, accelerator, crosslinking agent and special additives refined. Suitable for coating or spraying/drainage, compared with 2359 and 2360,2363 can not passivate EG products, such as the formation of a layer of colorless conversion coating, although containing cr3+ but has a good high temperature tolerance and corrosion resistance to the coating, in high temperature furnace adsorption effect is strong, improve the plate and metal in transportation and storage is not easy to change color performance

BT-2359 does not contain chromium ion, mainly composed of organic resin, silane, corrosion inhibitor and chemical process additives, is our company in order to replace chromate passivating of the new generation of environmental products. BT-2359 is suitable for spray gun spraying, for GI, GA, GL, EG and other plate surface passivation treatment, the formation of a layer of colorless conversion film, with excellent corrosion resistance and coating adhesion.

CL-2360 does not contain chromium ions and is mainly composed of organic resins, silanes, corrosion inhibitors and special auxiliaries. CL-2360 is a new generation of environmental protection products to replace chromate fingerprint resistance liquid. Suitable for coating or spraying/extrusion, passivation treatment of GI, GA, GL, EG and other sheet surface, forming a layer of corrosion resistance, no fingerprints on the colorless chemical film,

Compared with the traditional physical sealing method, passivation treatment has the characteristics of absolutely no increase in workpiece thickness and change color, improve the precision and added value of the product, so that the operation is more convenient;

Because the passivation process belongs to the non-reactive state, passivation agent can be repeatedly added and used, so the life span is longer and the cost is more economical.

Passivation promotes the formation of oxygen molecular structure passivation film on the metal surface, the film layer is compact, stable performance, and has a self-repairing effect in the air. Therefore, compared with the traditional coating method of rust prevention oil, passivation formed passivation film is more stable and more corrosion resistant (corrosion is an electrochemical change process, there are a few electric ions on the untreated metal surface, These ions move from the high-potential region (the cathode) to the low-potential region (the anode), thus generating a current. The action of this current will accelerate the destructive attack on the metal and produce corrosion, commonly known as rust, in the metal where the potential is weak.

Passivation role: play an auxiliary anticorrosive role. The gel formed by silica itself also has a certain isolation effect, preventing external moisture and gas from penetrating into the surface of the galvanized layer, and playing a certain role in auxiliary anticorrosion.

Improve the coating performance of the product. Silica is polar particles in the gel, so in addition to the passivation layer of other components adsorbed on the surface of the galvanized sheet, it can also play the role of a medium, and can be closely combined with the coating outside the passivation layer, the passivation galvanized sheet can not be painted, so that the passivation galvanized sheet can not only continue to paint, and coating performance is better. In fact, after adding silica, the passivation solution is more similar to the composition of color coating pretreatment solution. So passivated products can be used directly, but also as a color coated substrate.

Improve fingerprint resistance of the product. After the addition of silica, the effect of silica gel passivates the passivated film on the surface of the product more uniform, forming a very light and uniform light yellow, even if the adsorption of the fingerprint is more difficult to be detected, so in the general visual situation the fingerprint resistance of the product has been improved.

● Packing :25kg/barrel, 200kg/barrel, 1000kg/barrel.

● Storage :0-40°C in a cool and ventilated place.