Electrical Steel Insulation Coating

- BT

- SHENYANG

Electrical steel insulation coating is Chromium-free electrical steel coating,so can reduce the enviromental footprint for steel mills.

the functional coating applied to non-oriented silicon steel, without harmful solvents can add excellent corrosion protection for during storage and transport.

the passivation can reach to the requirment of customers, eg. corrosion resistance, weldability, machinability, high temperature annealing resistance and no powder falling, the most important is high surface insulation resistance.

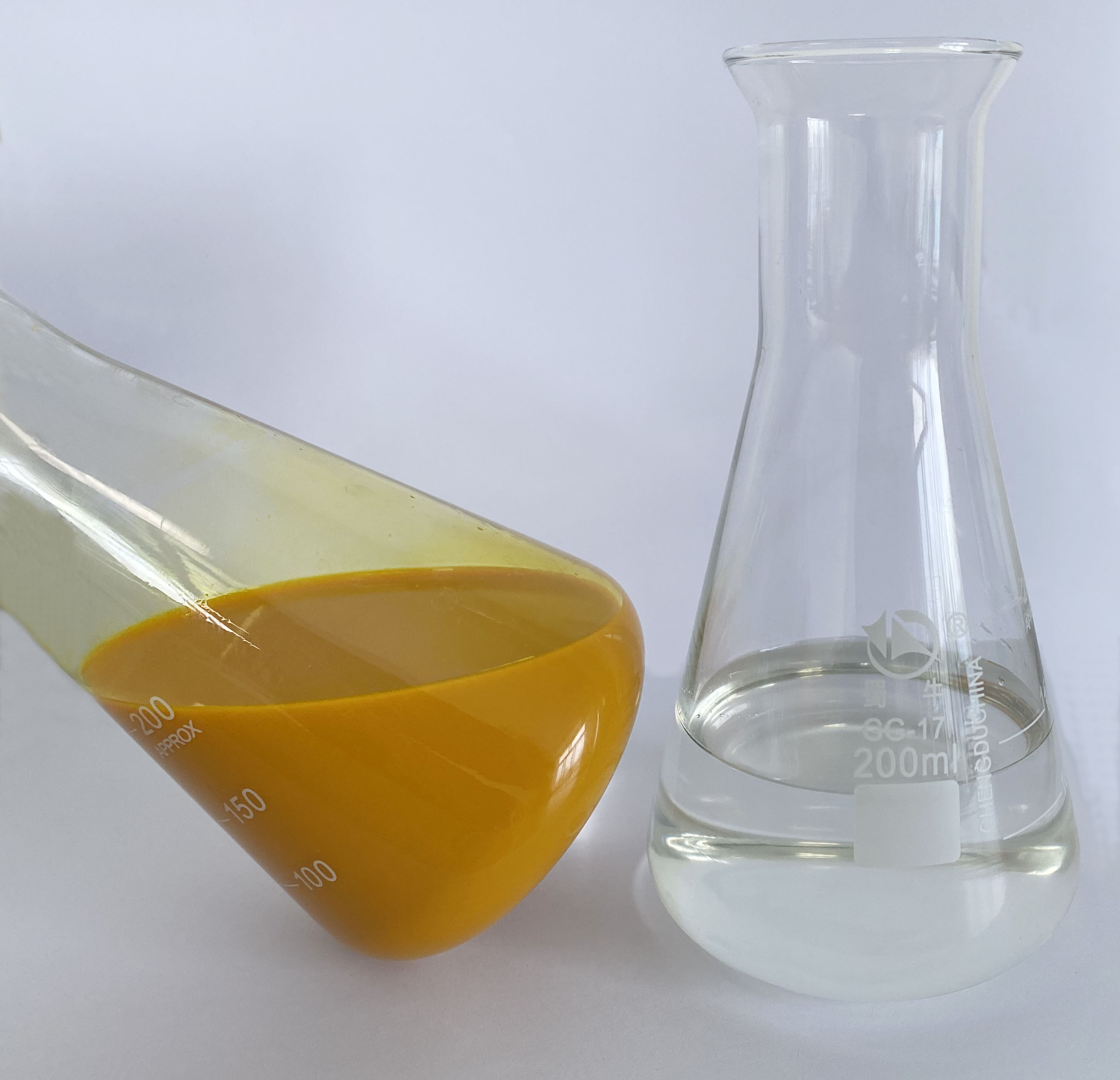

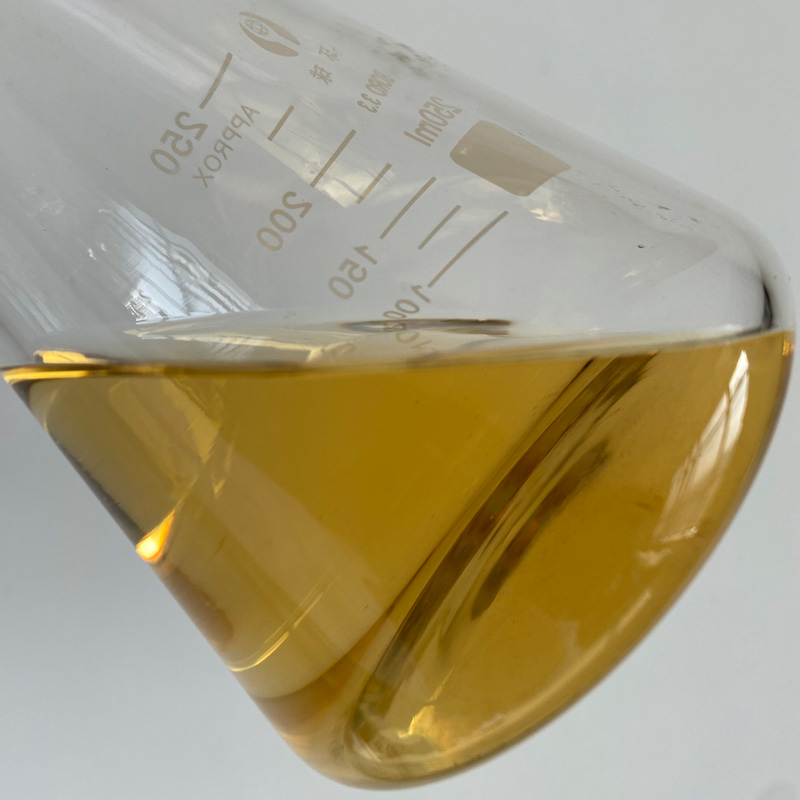

bt-2364 non-oriented silicon steel insulation coating liquid

bt-2364 is a low-foaming, semi-organic non-oriented silicon steel chromate insulating coating solution, which is prepared from inorganic, high-temperature-resistant organic emulsion and special additives. It does not contain harmful solvents and is suitable for roller coating. The coating liquid has good uniformity, stability and film-forming property. The color of the insulating coating is uniform and bright, with high surface insulation resistance, excellent adhesion, good surface mechanics, corrosion resistance, weldability, machinability, high temperature annealing resistance and no powder falling.

Coating liquid technical index

Appearance orange emulsion

Coating liquid components inorganic + high temperature resistant organic resin + special additives

Solid content 20-30% (depending on the type of coating roller)

pH 5.5 ± 0.5

Specific gravity 1.11 ± 0.10 g/ml

Viscosity (coated - 4 cups) 10 ~ 12 s (25 ℃)

Process 530~600℃, 20~30s

Bath temperature ≤ 25 ℃

Coating Specifications

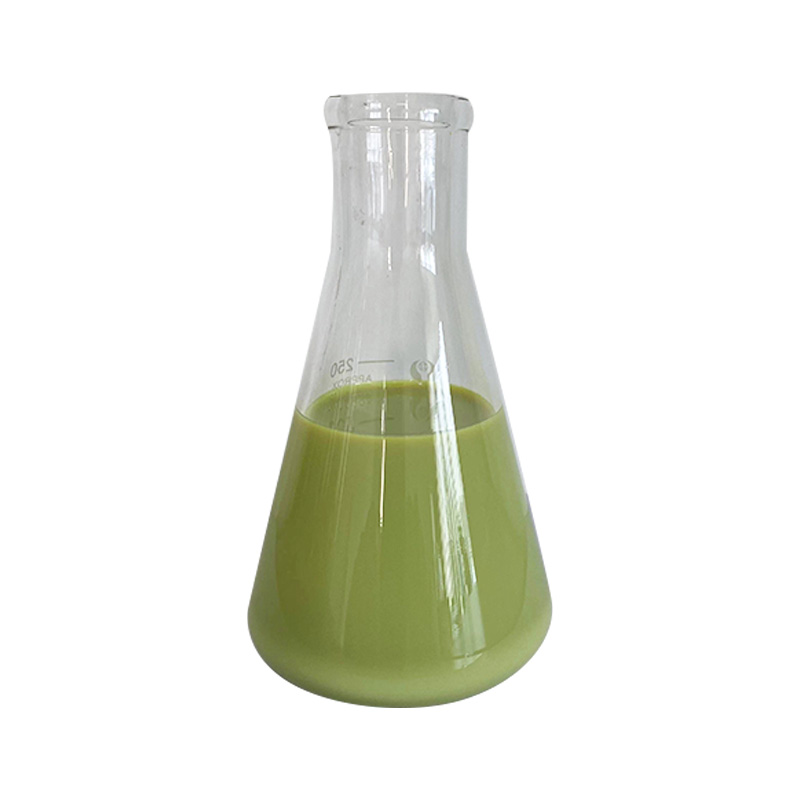

Appearance Light green or yellow-green (zinc system); white-gray or yellow-white (magnesium system), uniform and bright

Adhesion Grade A

Surface resistance ≥ 100 Ω/mm2 (0.5~1.2 μm)

Processability No peeling, no powdering

Heat resistance ≥ 750 ℃*2 hr (no shedding, no carbonization)

Salt spray resistance ≥ 24 hr

Refrigerant resistant R22 & R134a

Film performance ≥ 1.2 million times

Weldability ≥ 60 mm/min (no bubbles)

Features

²Comprehensive performance reaches and surpasses that of WISCO and Baosteel's chromium-containing coatings;

²Good coating workability, small coating foam, good leveling, no streaks, bubbles, orange peel and edge shrinkage and other defects;

²Excellent water resistance, solvent resistance and salt spray resistance, suitable for transportation and storage in coastal areas;

²Good hardness, good adhesion, mechanics, weldability and machinability.

packaging and storage

Packing: 25 kg/barrel. Other packaging forms can also be provided according to customer needs.

Storage: Store in a cool and airtight seal, store and keep as chemicals, and pay attention to antifreeze in winter.

Shelf life: three months.