Development of Waterborne Antirust Agent for Zinc Alloy Steel

Zinc alloy steel is widely used in various industries due to its excellent corrosion resistance and high strength. However, the formation of rust on the surface of zinc alloy steel can still occur under certain conditions, which can affect its service life and performance. Therefore, the development of a water-based antirust agent for zinc alloy steels is of great significance.

The development of a water-based antirust agent for zinc alloy steels involves several steps:

1. Chemical composition design: The chemical composition of water-based antirust agent for zinc alloy steelsshould be carefully designed to ensure that it can effectively prevent the formation of rust on the surface of zinc alloy steel. This includes selecting appropriate rust inhibitors, surfactants, and other additives that can enhance the performance of the antirust agent.

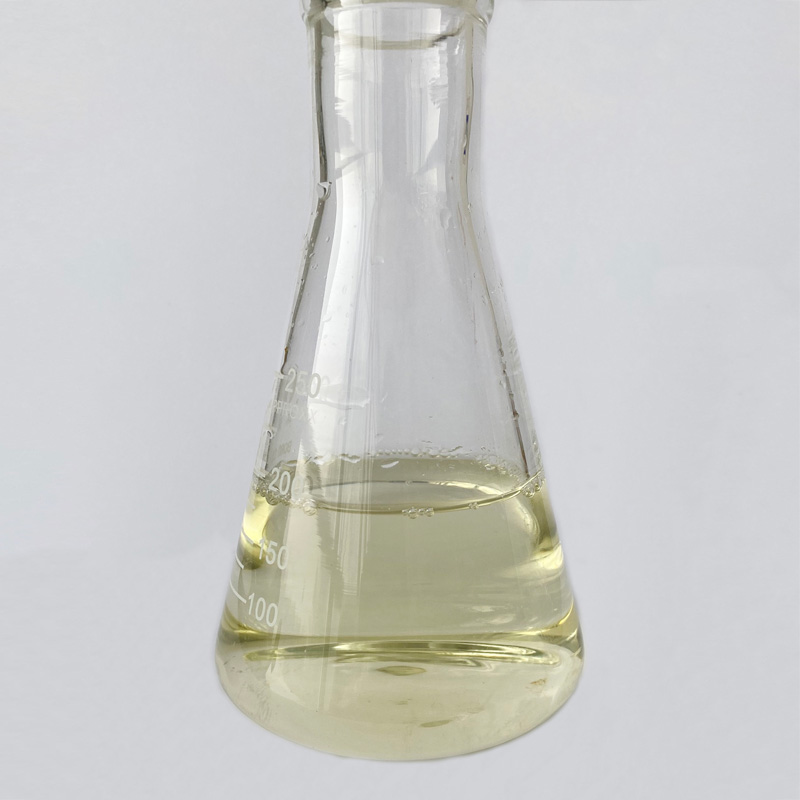

2. Preparation of water-based antirust agent for zinc alloy steels: The antirust agent can be prepared by mixing the selected chemicals in the appropriate proportions and then formulating them into a stable solution. The preparation process should be optimized to ensure that the resulting antirust agent has good stability and can be easily applied to the surface of zinc alloy steel.

3. Evaluation of the antirust performance: The antirust performance of the developed antirust agent should be evaluated through various tests, such as salt spray test, humidity cabinet test, and electrochemical test. These tests can help to determine the effectiveness of water-based antirust agent for zinc alloy steelsin preventing rust formation on the surface of zinc alloy steel under different conditions.

4. Optimization of the formulation: Based on the results of the evaluation tests, the formulation of water-based antirust agent for zinc alloy steelscan be further optimized to improve its performance. This may involve adjusting the concentration of the rust inhibitors or adding new additives to enhance the protective properties of water-based antirust agent for zinc alloy steels.

5. Application and maintenance: Once the optimal formulation ofwater-based antirust agent for zinc alloy steelsis obtained, it can be applied to the surface of zinc alloy steel using conventional coating methods, such as spraying or brushing. The application process should be carried out carefully to ensure that the antirust agent is evenly distributed on the surface. After application, regular maintenance should be performed to ensure that water-based antirust agent for zinc alloy steelsremains effective over time.

In conclusion, the development of a water-based antirust agent for zinc alloy steelsrequires careful consideration of its chemical composition, preparation, evaluation, optimization, and application. By following these steps, it